by Guest Columnist Danny Gierhart of the Asphalt Institute

“How thick should I specify the asphalt on my project, considering the number and types of traffic loads I expect, and the support I think the subgrade will provide?” That is the basic question posed by engineers who want their pavement to last a long time, and in good condition.

Pavement thickness designs are too often based on economics – how thick can the pavement be built with the dollars available for the project, regardless of the engineering realities. Or they are simply empirically based – what has been observed to perform under similar conditions before.

In the late 1950’s and early 1960’s, a large-scale experiment was performed by the American Association of Highway Officials (AASHO). Six pavement loops like the one shown in Figure 1, consisting of several different pavement cross sections, were continuously loaded to try to simulate a lifetime of fatigue in just a couple of years. The same level of traffic caused differing amounts of distress to the different sections. The analysis of the work resulted in a guide that has been used ever since, the AASHTO Guide for Design of Pavement Structures (the “T” for “Transportation” was added in 1973).

Figure 1. Photo of AASHO test section from Highway Research Board Special Report 61A-G

One of the strengths of the design process outlined in the guide lies in the fact that even though it is empirically-based, decades of experience have demonstrated that the method is fairly rigorous, and typically provides reasonable thicknesses as long as the data used to design the pavement is reliable.

However, one of its weaknesses is that the equations used for pavement analysis are very complicated. It took a certain level of training to properly use the nomographs and other tools necessary to make the calculations. Mechanistically-based pavement thickness design methods are even more complicated to use and have, to date, required sophisticated computer software and more specialized training. Pavement design engineers in state and federal agencies have the necessary training and resources, but often city, county, and private consulting engineers and managers do not.

But what if there was a way to design and document asphalt pavement thickness easily, that anyone could use? A way that used the accepted methodology of the AASHTO pavement design guide, a way that was user-friendly, a way that had easily accessible help, and best of all was FREE?

Pavia Systems, with sponsorship from the Asphalt Pavement Alliance (APA) and its constituent members, has developed online pavement thickness design software called PaveXpress (Figure 2). The software simplifies the process of using both the 1993 AASHTO design guide for asphalt pavements and 1998 AASHTO supplement for concrete pavements. The software is brimming with quick help buttons to assist the designer with obtaining and properly inputting the necessary information.

Figure 2. PaveXpress startup screen

PaveXpress can do much more than perform pavement thickness design. It contains a module which can give a simple material cost estimate for the pavement materials. The module is not detailed enough for use by bidders for contract estimation purposes, but can be a tool for agencies and consultants to get a rough idea of pavement material costs.

It also contains a module which can analyze a pavement structure using a more mechanistic type of methodology, which considers the material properties for a given pavement cross section, the anticipated stresses induced by the traffic loading, and the response locations on the pavement surface and at selected points within the pavement structure. The user is allowed to select an analysis regarding the type of transfer functions to be used, which results in an estimate of the number of load cycles to failure.

The software developers are currently working on a module which can be used to estimate life cycle costs. Life-cycle cost analysis is one of the tools by which different pavement structures are evaluated and eventually selected by pavement owners. The life-cycle cost of a road includes considerations such as the initial cost of construction of a road, anticipated maintenance costs over its lifetime, and the costs to users for their delays during maintenance and reconstruction.

The rest of this article will focus on PaveXpress’s ability to estimate a required pavement thickness to support anticipated traffic over a user-defined design period utilizing specified materials.

The process is accomplished on a step-by-step basis. The designer must select the type of design to be performed: new full-depth asphalt, new full-depth concrete, asphalt overlay over existing asphalt, or an asphalt overlay on concrete or composite pavement.

PaveXpress also requires the designer to select the type of roadway the pavement is being designed for: interstate, regular highways or arterials, local roadways, or residential streets. Default values in other areas of the program are populated based on the type of roadway selected. However, any default value can be easily overridden by the designer when desired.

Next, the designer can either keep the default deign period populated by the roadway type selection or override it with a different design period. The default values for new construction range from 20 years for local and residential streets to 40 years for interstate highways.

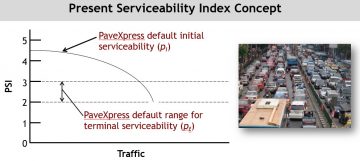

The designer can either keep the default value or provide a different estimate of the expected ride quality immediately after construction in the form of a present serviceability index (PSI). The PSI is a subjective measure of ride quality using measurements of roughness and distress, e.g. cracking and patching, and rut depth.

In the same way, the designer can either keep the default value or provide a different estimate of the terminal serviceability index, which is how far the designer will allow the pavement to deteriorate before it is considered to be at the end of its useful service life.

Figure 3. Illustration of the Pavement Serviceability Index concept

The AASHTO Guide for Design of Pavement Structures requires some statistical values that are used to estimate the probability that the pavement will survive the design period with a pavement serviceability level greater than the terminal serviceability level. PaveXpress again provides reasonable default values for these statistical values, which may be overridden if the designer desires.

Another step requires the designer to provide estimates of the traffic predicted throughout the roadway’s design life. Several different methodologies to estimate the traffic are provided in PaveXpress. These methodologies typically include the use of current traffic volumes, breakdowns of the type of traffic (cars, busses, and various configurations of trucks), and projected traffic growth rates.

The designer then inputs the layer types (e.g. subgrade, aggregate base, asphalt mixture) and material layer coefficients. Again, default values are provided based on the material type. PaveXpress even provides a link to an excellent National Center for Asphalt Technology (NCAT) report on asphalt layer coefficients.

Finally, the designer inputs expected resilient modulus values for each layer in the sub-structure. The program provides reasonable defaults, but actual test data or historically-proven values for each layer type are preferable for the greatest accuracy. If the designer is uncertain regarding the numbers, there are many documents available which can provide confidence that the values are “in the ballpark.” For example, Asphalt Institute’s IS-91 provides reasonable values for poor, medium, and good-to-excellent subgrades for R-values, California Bearing Ratio, and resilient modulus.

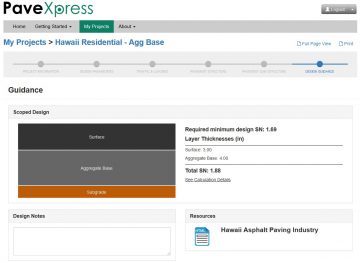

The program then calculates the layer thickness(es) for which the average number of expected traffic loads over the design life can be carried, given the specific statistical, traffic, and material inputs. The program runs very quickly, allowing the designer to input a variety of scenarios for the same roadway, which can increase confidence in the final design.

Figure 4. Example of PaveXpress design guidance.

In summary, PaveXpress is an excellent tool for pavement thickness design which duplicates the analysis of the AASHTO 1993 pavement design guide for asphalt and the 1998 supplement for concrete. It does not unfairly promote one type of material over another, or give unreasonable results for either asphalt or concrete. The designer needs only to collect the best possible project, traffic, and material information in order to provide the best accuracy. It is free and easy to use, making it an exceptional tool for those pavement designers without access to larger agency tools and expertise.

PaveXpress is an online tool that can be found at: http://www.pavexpressdesign.com/