Top-Down Cracking

Top down cracking appears to be a common mode of HMA pavement distress in at least several states and countries. Traditionally, pavement cracking is thought to initiate at the bottom of the HMA layer where the tensile bending stresses are the greatest and then progress up to the surface (a bottom-up crack). Most traditional transfer functions used in mechanistic-empirical structural design are based on this concept. However, the late 1990s saw a substantial focus on a second mode of crack initiation and propagation: top-down cracking.

Figure 1: Likely Top-Down Cracking on I-37 South of San Antonio, TX

Although still not completely understood at this time (2003), there

are three basic contributors to the top-down cracking mechanism:

- High surface horizontal tensile stresses due to truck tires

(wide-based tires and high inflation pressures are cited

as causing the highest tensile stresses).

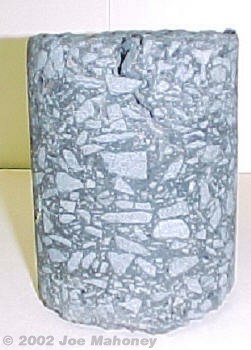

Figure 2: Top-Down Crack Core - Age hardening of the asphalt binder (especially at the surface) resulting in high stresses in the HMA and low resistance to cracking.

- A low stiffness upper layer caused by high surface temperatures.

The mechanism is a combination of the above. The bottom line is that HMA top-down cracking is a real phenomenon and should be considered as a causative factor for pavement cracking. Two simple suggestions may help in the identification of top-down cracking:

- In thick HMA pavements, consider top-down cracking as a possible cracking mechanism. Generally, previous research has found that in pavements thicker than about 6 inches top-down cracks can be and often are the dominant form of cracking. Do not assume pavement cracks are bottom-up.

- Before deciding on a maintenance and/or rehabilitation strategy, take a pavement core on a suspect crack (see Figure 2). Usually, a pavement core will show whether a crack is top-down or bottom-up. It will also show the extent to which the crack has propagated, thus defining the extend of needed milling prior to overlay.

Often, if top-down cracking is caught early enough a repair strategy of milling off the cracked layer of HMA and replacing it with a new layer can essentially restore the pavement to a like-new condition. This is an essential premise of Perpetual Pavements.