Pavement Facts

There are over 4 million public centerline road miles (8.48 million lane miles1) in the U.S. and of this, 2.73 million miles (or about 67 percent) are paved (FHWA 2009). This section contains several quick pavement facts that serve as a good basic background for the rest of the Guide.

Pavement Purpose

Typically,

pavements are built for three main purposes:

- Load support. Pavement material is generally stiffer than the material upon which it is placed, thus it assists the in situ material in resisting loads without excessive deformation or cracking.

- Smoothness. Pavement material can be placed and maintained much smoother than in situ material. This helps improve ride comfort and reduce vehicle operating costs.

- Drainage. Pavement material and geometric design can effect quick and efficient drainage thus eliminating moisture problems such as mud and ponding (puddles).

Pavement Categories

Pavements can be broken down into two broad

categories:

- Flexible pavements. These are asphalt pavements (sometimes called bituminous pavements), which may or may not incorporate underlying layers of stabilized or unstabilized granular materials on a prepared subgrade. These types of pavements are called "flexible" since the total pavement structure bends (or flexes) to accommodate traffic loads. Flexible pavements comprise about 94 percent of U.S. paved roads (about 98 percent of Hawai'i roads).

- Rigid pavements. These are portland cement concrete (PCC) pavements, which may or may not incorporate underlying layers of stabilized or unstabilized granular materials. Since PCC is quite stiff, rigid pavements do not flex appreciably to accommodate traffic loads. Rigid pavements comprise 6 percent of U.S. paved roads (about 2 percent of Hawai'i roads).

Hot Mix Asphalt (HMA) Defined

Hot mix asphalt (HMA) is a bituminous concrete made principally

from asphalt

binder and aggregate.

It is distinguished from other bituminous products by its

constituent materials

(asphalt

and aggregate), mixture

design methods and elevated mixing

temperature (thus the term "hot mix"). Although

it is known by many different names such as hot mix, asphalt

concrete

(AC or ACP), asphalt, blacktop or bitumen, this Guide makes

a conscious effort to consistently refer to this material

as HMA. Other types of asphalt-based pavement surfaces

discussed in this Guide such as fog

seals, slurry

seals and chip seals are

not HMA but are nonetheless important to the pavement industry. Warm mix asphalt (WMA) is essentially the same material as HMA except that a special procedure, additive or material(s) have been used to reduce mixing temperate. WMA is considered a subset of HMA in this Guide.

[More

information]

Tar vs. Asphalt

Tar and asphalt are two different materials. Tar, often

called "coal

tar" is a byproduct of the destructive distillation

of wood or coal to form coke. Coal is of plant origin and was formed

in

swamps similar to present-day peat bogs and in lagoons,

probably partly from plants growing in the area and partly

from plant

material carried in by water and wind. Asphalt is a petroleum residue left

over from the distillation of crude oil. Crude oil is the

result

of incompletely decayed ancient plant and animal remains.

The carbon chains within tar are, in general, slightly

shorter than those in asphalt. In pavement applications,

tar is generally

more brittle and less elastic than asphalt causing it to

crack

under typical loading and environmental conditions. Tar

will, however, not dissolve as easily in the presence of

lighter

petroleum distillation products such as gasoline and kerosene.

While asphalt is used throughout the pavement industry,

tar is generally limited to sealant use. Coal tar sealant is coming under increased scrutiny and has been banned in many areas because of its association with polycyclic aromatic hydrocarbons (PAHs) found in streams and parking lot dust reported in research (e.g., Van Metre et al. 2009; Watts et al. 2010; Mahler et al. 2012).

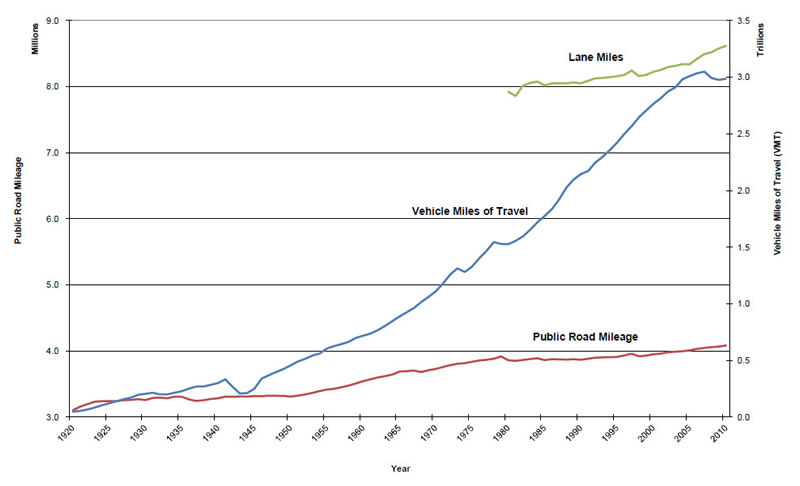

Road Use

U.S. and State roads are being used at an ever increasing

rate. Although U.S. road centerline miles have only increased

by

about 10 percent since 1960, U.S. registered vehicles

have increased by over 300 percent and vehicle miles traveled

have increased by more than 400 percent over that same

time. In sum, our road network, which has not significantly

expanded

since 1960, is now carrying over 4 times the number

of

vehicles. Moreover, truck (the most damaging type of

vehicle) vehicle

miles traveled (VMT) is increasing at an even faster

rate than automobile VMT. A typical tractor-semi trailer combination

averages 100 - 200 miles/day in the U.S. for a total

of

35,000 - 70,000 miles/year, which is substantially more

than the

typical

passenger vehicle (USDOT, 2000). Thus, pavement loading

is growing at an even faster rate than traffic.

| HAPI Pavement Note on Hawai'i Road Use |

Hawai'i has 4,371 centerline miles of roadway (9,523 lane-miles1). As of 2012, Hawai'i's population was just under 1.4 million and of that about 1 million (or 75%) were of driver age with about 890,000 licensed drivers and over 895,000 registered vehicles. These vehicles traveled approximately 9.973 billion miles in 2009 (the lastest data year at the time of this publication) at an average of just over 11,000 miles per vehicle (7,254 miles per capita). Of note, that is about 1,000 miles more per vehicle than was reported in 2001.

|

Figure 2: Growth of vehicle miles traveled (VMT),

registered vehicles and

statute miles of roadway in the U.S. since 1960 (from FHWA

2010).

Other Pavement Uses

HMA is used in many applications beyond roads. HMA is by far

the most popular airfield

pavement (about half of all major airport runways are surfaced with HMA while well over 90% of all airport runways are surfaced with HMA) and can also be used in drainage

swales, retention pond and reservoir applications

as well as other specialty applications (see Figure 3).

Figure 3: Paving the base layer for the field turf installation at Aloha Stadium.

Figure 4: Paving at Honolulu International Airport.

Note 1: A centerline mile is based on a road's physical length regardless of the number of lanes. A lane mile is based on the total length of lanes. For instance, a 1 mile road with four lanes would constitute 4 lane miles.